Case Study – Leveraging mmWave Radar Sensors for Jackknife Warning and Coupling Guidance

Client Overview

VBG Coupling Systems is a part of VBG Group, an international engineering group founded in 1951 with more than 1800 employees in 16 countries. The company is the leader in its segment of the transport industry in the Nordics and the United Kingdom and a pioneer in developing trailer coupling systems utilizing the latest technology.

The Problem

VBG Coupling was looking to build an innovative product – VBG Driver Assist – that would help truck drivers couple trailers and reduce the risk of damage or injury. The company needed a technology that would provide reliable and accurate sensing around the backside of the truck and help the driver navigate the vehicle with ease and precision.

Challenge #1 – Jackknifing

Jackknifing is one of the most common types of truck accidents that occurs when the front vehicle skids but the trailer attached to it does not slow down or stop. This causes the trailer to push the towing vehicle to the side or spin it around until it faces the trailer backwards. When the driver loses control of the vehicle, it can lead to serious damage, injury, or death.

The existing warning systems will only activate after jackknifing has occurred. There is no warning beforehand to alert the driver that jackknifing is about to happen and help them avoid it.

Challenge #2 – Coupling Guidance

Typical coupling assistance systems have a rear camera that helps the driver couple the trailer. Since there is only limited visual information available, the driver often has to step out of the cabin and check if the truck is at the correct height for coupling, which is a time-consuming process.

Camera lenses get dirty from rain, dust, or mud and require regular cleaning. Cameras become unreliable in reduced visibility conditions caused by the elements or poor lighting.

The Solution

Our team of radar experts has proposed a solution that would solve both the jackknifing and coupling challenges. NOVELIC was involved in all the steps from PoC to the final product, providing system design, data processing algorithms, hardware and software development, as well as enclosure design.

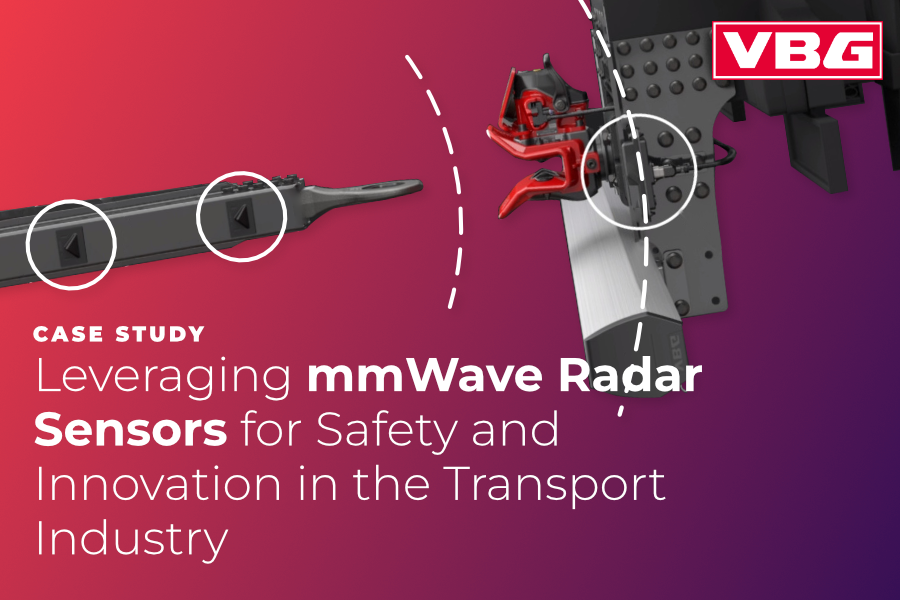

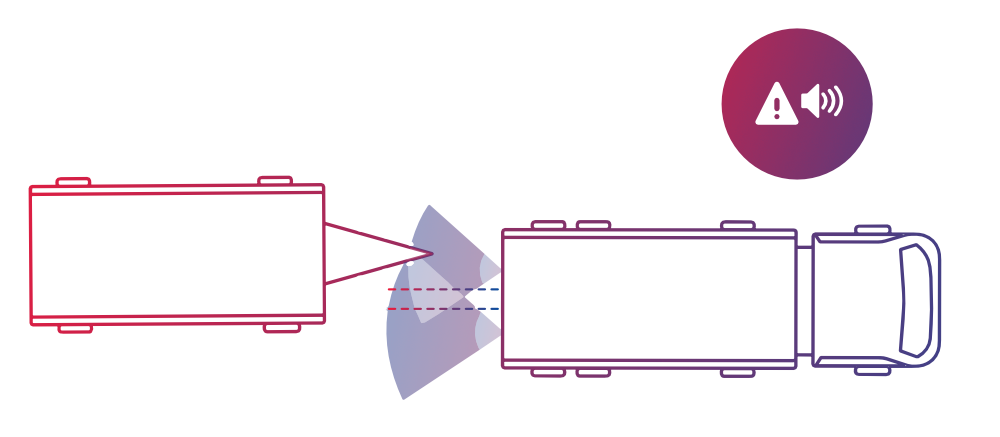

The solution is based on 79 GHz mmWave radar sensors placed on the back of the truck. The sensors send electromagnetic waves that reflect off the passive corner reflectors placed on the trailer and the data processing of the returning signal allows for precise calculations of the drawbar position in 3D space (distance, horizontal, and vertical angle). This data is sent to the truck environment via a CAN bus, triggering sound alerts and providing display information (to be realized in the near future). All signal processing is done in the sensor module, so no external processing is needed.

When the angle between the trailer and the truck reaches a critical value, a sound alarm will alert the driver that there is a risk of jackknifing. The audio signal is triggered at an angle of 40 degrees and increases in frequency the closer the rig is to the jackknife angle. This provides the driver with enough time to react and avoid jackknifing.

”Right from the start of the development project we had a good engagement. Of course we had some challenges during the way but the goal was clear for both parties. Novelic gave us good support and they also felt a sense of urgency when it was needed. The end product is now delivering a great functionality, so we are very satisfied with the collaboration.” – VBG Group Truck Equipment

The coupling guidance system gives the driver precise direction and distance instructions for coupling. There is no need for the driver to leave the cab and visually inspect the drawbar position, which makes the coupling process faster and more efficient.

Since radar waves pass through non-conductive materials, the sensors can be completely covered in mud or dirt and work with 100% reliability. Radar sensors are not influenced by light, so they will work in pitch dark or sun glare. The radar casing has an IP69K rating, meaning the sensor is dustproof, resistant to high temperatures, and can withstand high-pressure washdown.

Highlights

- Increased safety and equipment protection

- High-precision driver assist system

- Easy aftermarket installation for any type of trailer

- Low-power, no external data processing required

Increased Driver Safety

Shorter coupling time

Fewer vehicle repairs