Power Electronics

On-board chargers for eMobility

NOVELIC offers on-board charger (OBC) solutions for electric vehicles, ranging from 6.6 kW to 11 kW applications. Our OBCs are efficient, three-phase designs based on SiC-MOSFET technology.

Fast Charging

Universal input with PFC operation

Three-phase solutions

Bidirectional operation for V2L and V2H modes

Customizable & expandable

Liquid & air cooling

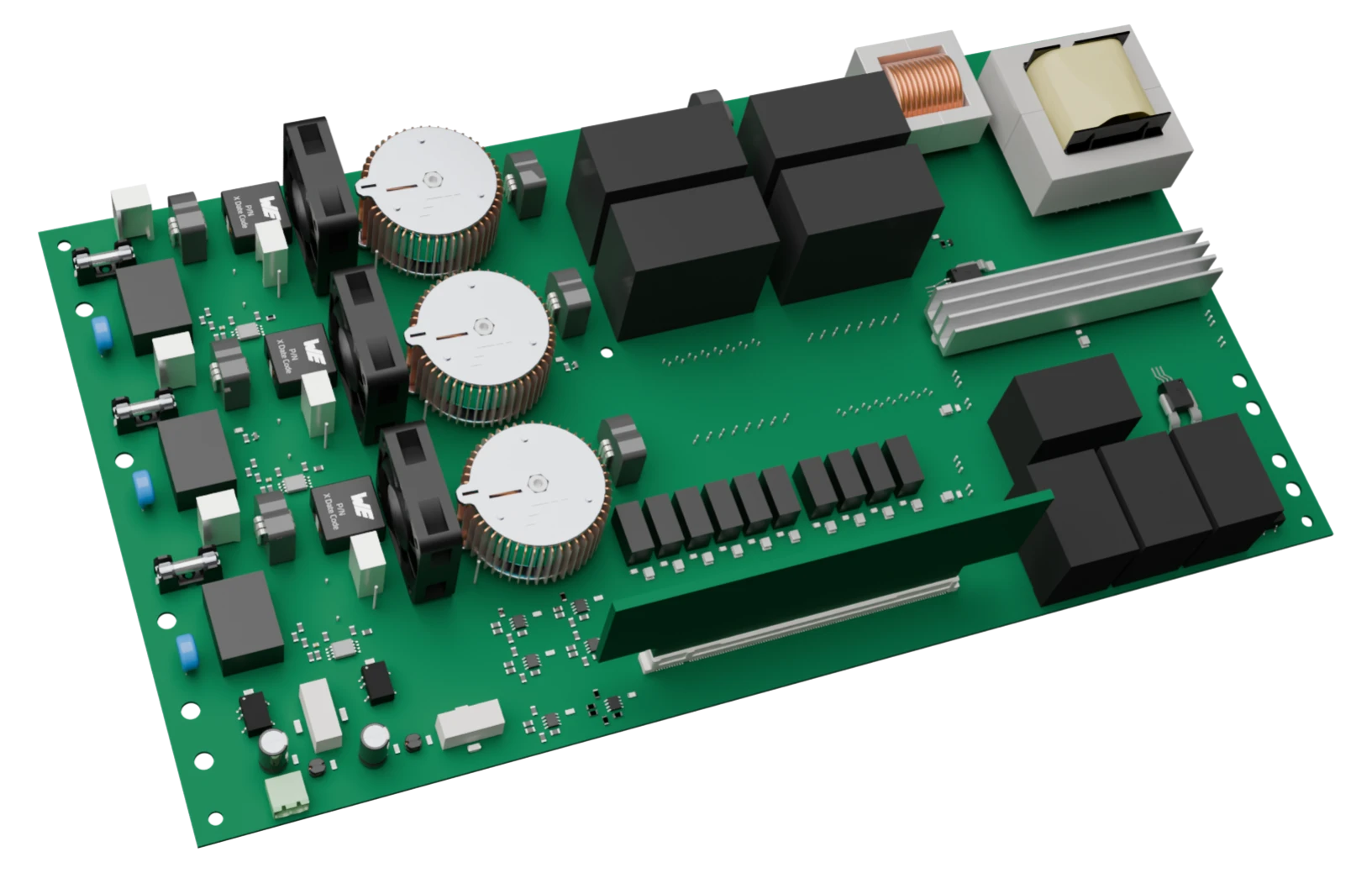

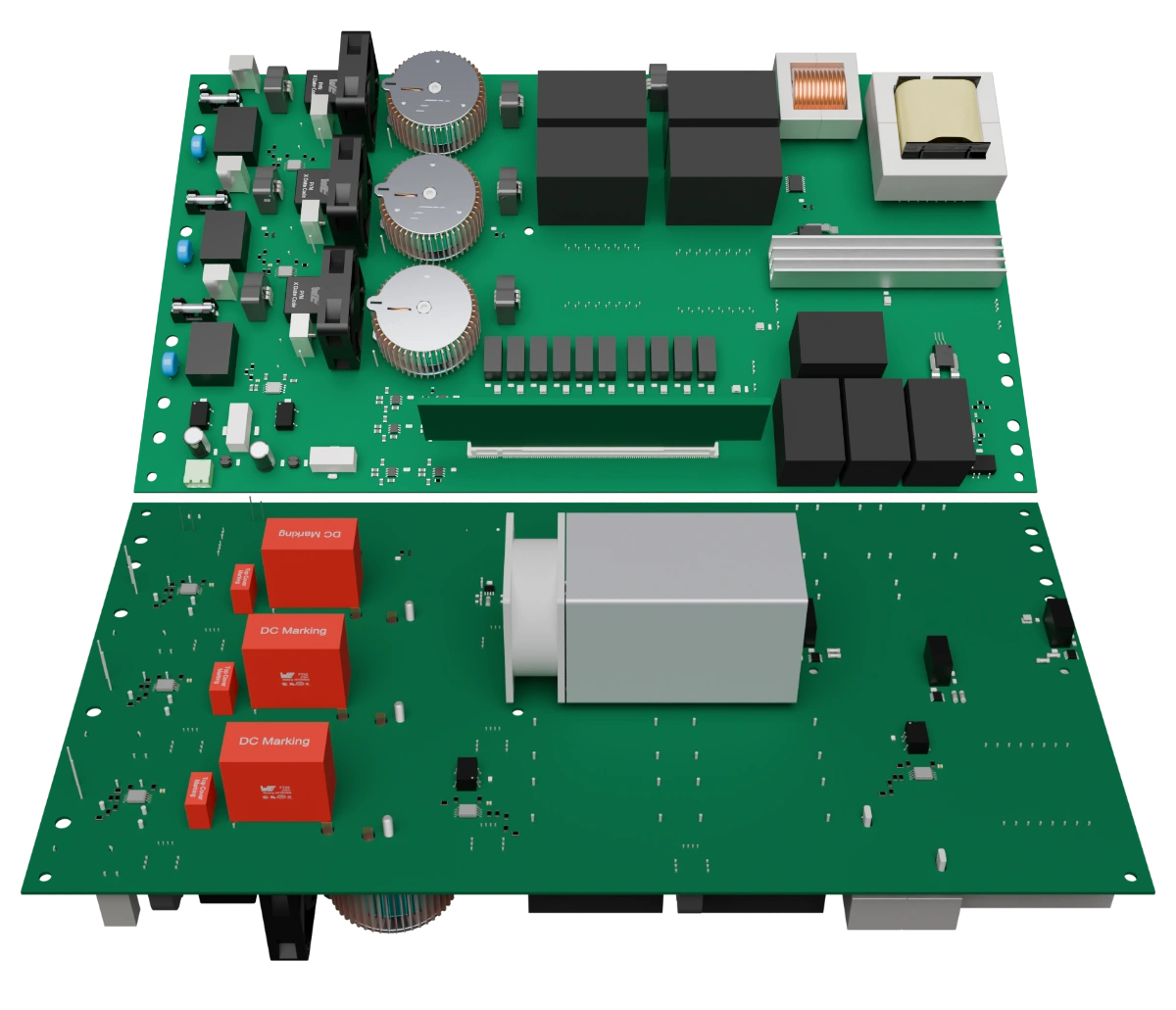

72V / 6.6kW On-Board Charger for two wheelers and three wheelers

This on-board charger (OBC) is used to charge the battery in two- and three-wheelers from AC grid while the vehicle is parked. The development target is efficient power conversion for 72 V systems with increased power density and reliability.

Additionally, a bidirectional power flow feature is implemented to support V2L and V2H operation as needed.

The pictured board is a reference design. Any solution is customizable to the client’s needs.

Use Case – Hardware Platform

Designed on a single board featuring:

- Full SiC AC-DC converter, including

- input relay at each phase

- passive input EMC filter

- three-phase bidirectional PFC stage for universal input

- Full SiC DC-DC converter based on Dual-Active-Bridge with ferrite transformer for galvanic isolation

- Polypropylene film capacitors in DC circuits used to avoid issues related to use of electrolytic capacitors

- Separate power + measurement and control board

- Full galvanic isolation between power/measurement and control-board

- External water-cooling or forced-air cooling with integrated long-life fans

Use Case – SiC Power Stage

A full SiC-MOSFET power stage provides improved efficiency and smaller volume.

The application of top-side cooled compact semiconductor modules and transistors offers additional advantages:

- Lower board space

- Lower losses due to paralleling transistors on high-current side of DC-DC converter

- Top-side cooling for easier and cost-effective assembly of heatsinks

- Separate power + measurement and control board

- Better integration of switches for decreased stress and EMI issues

All gate-driver ciruits are galvanically isolated and provide a high CMI immunity level.

Use Case – Control section

Each converter is controlled by a dedicated 32-bit high-performance microcontroller designed for digital power conversion:

- Wide range output voltage regulation and accurate charge current control

- High-precision measurement and control

- Floating point unit with math accelerators support for quick and efficient execution of demanding control algorithms

- High-resolution PWM timers for precise generation of driving signals

- Main communication with vehicle control system using a CAN interface

- Wide-range of additional communication capabilities

Customization

| Design | Single-board, or modular – for space-saving designs. For lower power outputs, single phase is also available |

| Cooling | forced-air or liquid |

| Stacking | possible, to increase the output power level |

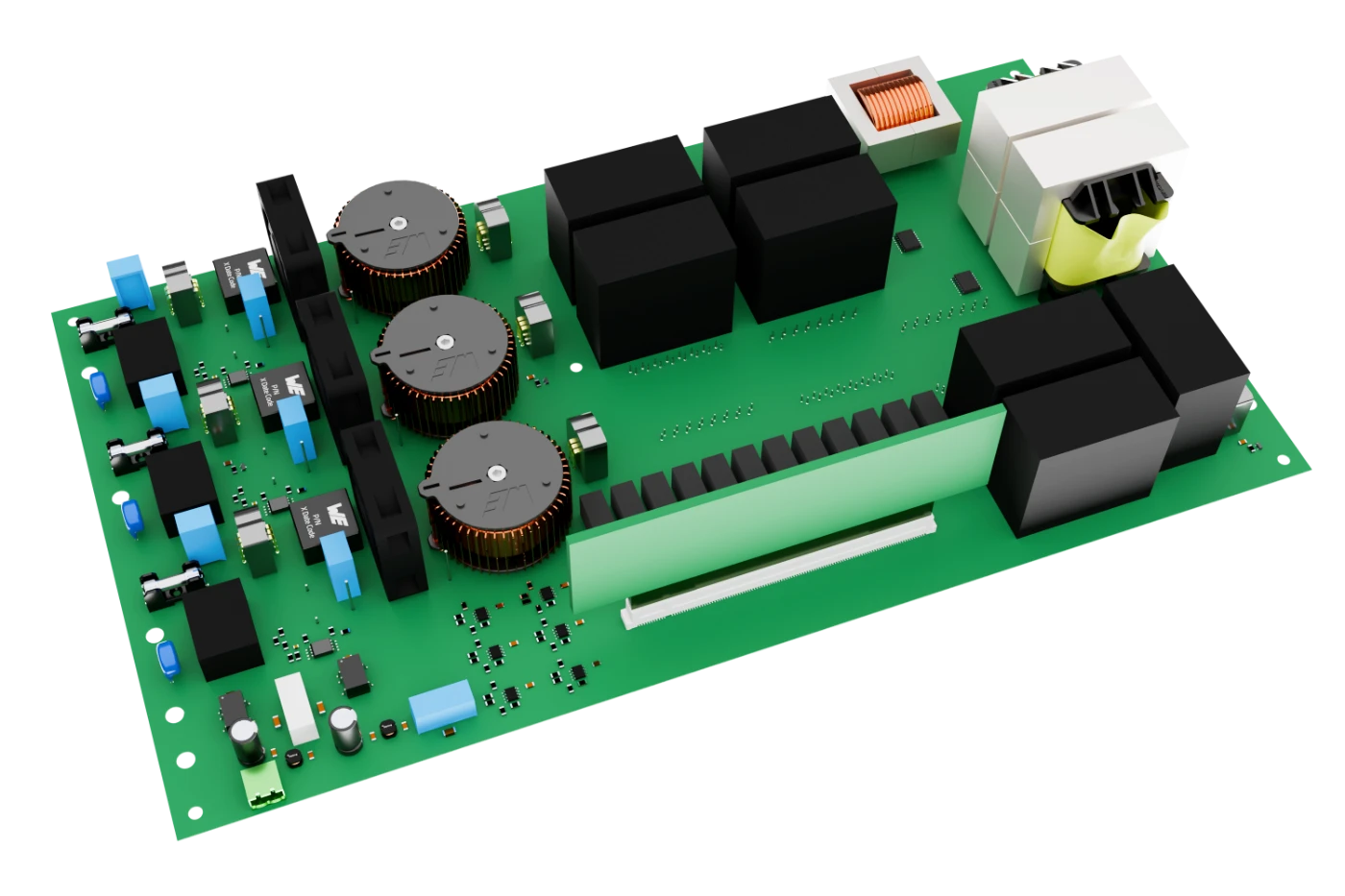

11 kW On-Board Charger

The EV on-board charger (OBC) recharges the high-voltage (HV) main battery from AC grids while the car is parked. Typical development targets are efficient power conversion for 400 V and 800 V systems, power density, reliability, and bi-directional powerflow to enable V2L, V2H, and V2G.

The pictured board is a reference design. Any solution is customizable to the client’s needs.

Use Case – Hardware Platform

Designed on a single board featuring:

- Input relay at each phase

- Passive input EMC filter

- Three-phase bidirectional PFC stage for universal input

- Dual-active-bridge with ferrite transformer for galvanic isolation

- Polypropylene film capacitors used to avoid aging and thermal issues with electrolytic capacitors

- Separate power + measurement and control board

- Full galvanic isolation between power/measurement and control-board

- Forced-air cooling with long-life fans

Use Case – SiC Power Stage

A full SiC-MOSFET power stage provides improved efficiency and smaller volume.

The usage of compact semiconductor modules offers additional advantages:

- Lower board space

- In-line positioning for better utilization of heat-sinks

- Top-side cooling for easier and cost-effective assembly

- Separate power + measurement and control board

- Better integration of switches for decreased stress and EMI issues

All gate-driver ciruits are galvanically isolated and provide a high CMI immunity level.

Use Case – Control section

Each converter is controlled by a dedicated 32-bit high-performance microcontroller designed for digital power conversion:

- Wide range output voltage regulation and accurate charge current control

- High-precision measurement and control

- Floating point unit with math accelerators support for quick and efficient execution of demanding control algorithms

- High-resolution PWM timers for precise generation of driving signals

- Main communication with vehicle control system using a CAN interface

- Wide-range of additional communication capabilities

Customization

| Battery voltage | 400V or 800V |

| Power level | 6.6kW, 11kW, or 22kW |

| Design | single-board, or modular – for space-saving designs |

| Cooling | forced-air or liquid |

| Stacking | possible, to increase the output power level |